Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Henan Shunbang Chemical Industry CO.,Ltd

cherrychen@shunbangchem.com

86-0371-65582722

![]() November 15, 2022

November 15, 2022

Japan's Soda Co., Ltd. and Idemitsu Kosan Co., Ltd. use nitrogen, helium, and air to remove carrier gases, and introduce titanium alkoxide vapor into the reaction zone of the reactor for instantaneous mixing and rapid hydrolysis. The particle size and particle shape of the nano TiO 2 are adjusted by changing the residence time, molar ratio, flow rate, concentration, and reaction temperature of various vapors in the reaction zone. This preparation process can obtain amorphous nano-TiO 2 having an average primary particle diameter of 10 to 150 mm and a specific surface area of 50 to 300 m 2 /g. If titanium alkoxide vapor, water vapor and organic surface treatment agent are introduced into the reactor together, after the titanium alkoxide vapor is vapor-phase hydrolyzed to form nano-TiO 2 , the TiO 2 particles can be further subjected to an organic surface treatment, and the prepared nano-TiO 2 can be used. In the field of paints, polymer materials and other catalysts. This process is characterized by low operating temperatures, low energy consumption, low material requirements, and continuous production. The disadvantage is that the raw material cost is high and the rutile-type nano TiO 2 cannot be directly synthesized.

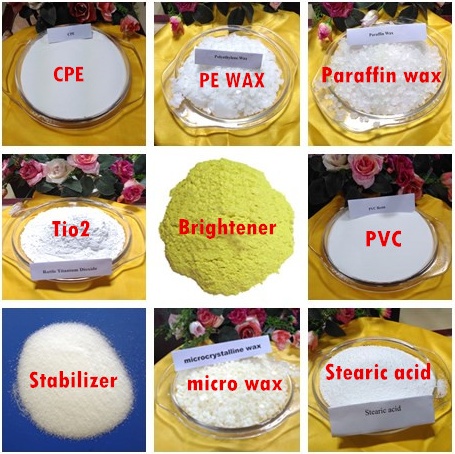

We have done chemical products for over 30years. Our main products include PVC Resin, CPE, TIO2, Pe Wax, Paraffin Wax, Stabilizer, Stearic Acid ETC.

The above is the Preparation method of nano titanium dioxide---Titanium alkoxide gas phase hydrolysis method we have listed for you. You can submit the following form to obtain more industry information we provide for you.

You can visit our website or contact us, and we will provide the latest consultation and solutions

Send Inquiry

Most Popular

lastest New

Send Inquiry

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.