Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Henan Shunbang Chemical Industry CO.,Ltd

cherrychen@shunbangchem.com

86-0371-65582722

After understanding the significance of its existence, let's take a look at its classification and functions?

Lubricants mainly include internal lubricant and external lubricant

1. Main functions of internal lubricant and external lubricant

The main function of the internal lubricant is to weaken the interaction between the internal chain segments of the polymer, make the polymer molecules slide easily, and improve the fluidity of the polymer melt. This lubricant is compatible with the polymer molecules and can be evenly distributed around the polymer molecules, such as the common processing aid: Stearic Acid

The main function of the external lubricant is to make the surface of the product shiny, easy to demould, and prevent adhesion on the surface of the product. They have poor compatibility with the resin, and cannot be evenly dispersed around the resin molecules, and cannot be dispersed inside. Generally, the amount of external lubricant should not be too much, which may cause frost or stickiness on the surface. E.g. Polyethylene Wax

2. Main functions of internal lubricant and external lubricant

The function of internal lubricant is mainly to weaken the attraction between macromolecular chains, make them slide easily, and reduce the interface friction; The powder resin is stably gel; Reduce the melt viscosity of the resin and improve the fluidity of the resin; Improve production capacity and reduce mechanical load.

The main function of the external lubricant is to reduce the aging and decomposition of the resin due to local overheating; Improve the surface gloss of plastic products; Make the products easy to demould and prevent the products from adhering to the mold surface.

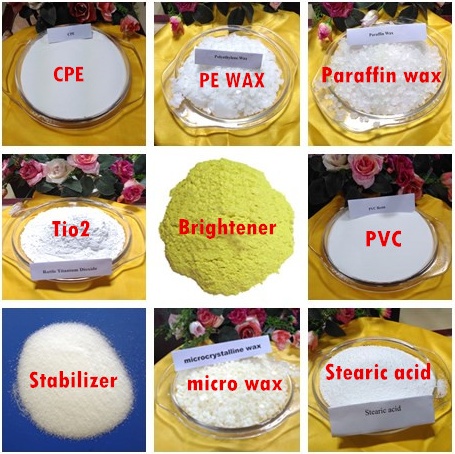

We have done chemical products for over 30years. Our main products include PVC Resin, CPE, TIO2, Paraffin Wax, Pe Wax, Stabilizer ETC.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.